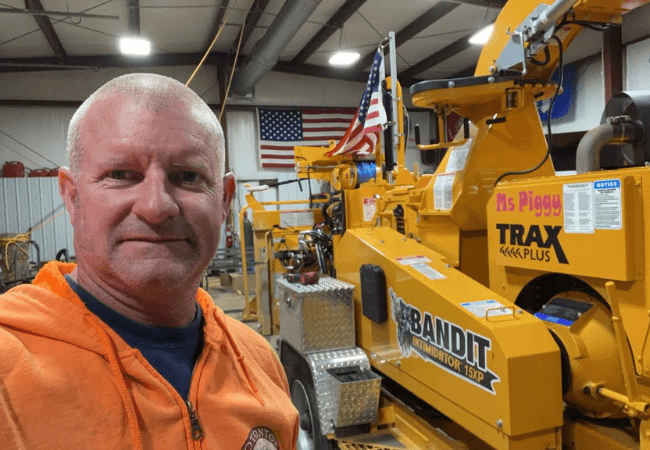

If you are looking for a perfect bandit chipper troubleshooting guide then we have put together one for you. But, first things first, relax.

It may sound like a huge deal that your Bandit Chipper new or old is not working but it will all be alright real quick. So, let’s get into it.

Quick Bandit Chipper Troubleshooting

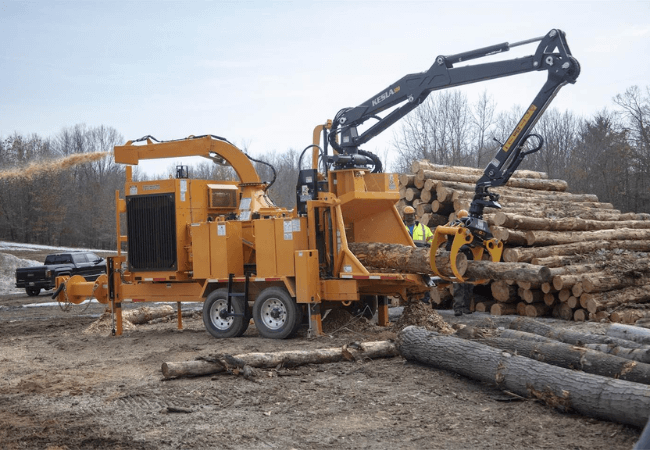

The quickest way to fix your Bandit Chipper is to make sure that the engine is starting up as per routine and that you are giving your machine adequate time to warm up.

Knowing where the problem lies starts with understanding how it operates and at which stage the issue arises.

If your engine sounds normal and is starting up just fine then you need to check the chipper’s ability to pull in, crush and compress the trees or stumps that come in front of it.

If you are facing problems here then the issue is likely to be with the grinding equipment.

Fitting Faults

For this make sure that you are testing the chipper on a smaller tree or a less stubborn top.

Although if there is a problem with the chipper you will notice a change over time and more of a transition toward poor performance.

However, if you feel like suddenly the chipper has stopped grinding then it is likely that the unit has a fitting fault or an issue with one of the parts.

For this, you will have to get in deeper and find the root cause. Don’t worry we will help you find it.

Performance Issues

If grinding is not your problem but fuel efficiency or the chip quality are your concerns then the matter is about the performance.

For this case, you will have to reverse a bit. You will have to check everything wrong that possibly went with your chipper in terms of misuse or improper usage in the past few days.

Boot Up Issues

If you have not been using your chipper for a while but still noticing issues with the engine then there is a possibility that your chipper is out of order.

You should give it an engine restart followed by a long warm-up time so that all parts are ready for action once again.

Rust, breakage, and other forms of damage can cause such issues with the parts.

Although the company claims that all bandit chippers are built by specialized engineering teams who use only the highest machine components that are rust protected and properly welded some one-off cases do get issues or defects, but the company provides long-lasting service warranties for such cases.

You do not need to worry about them, just contact the support and they will look at your machine to fix the issue.

Horsepower Issues

You can choose the chippers to be in an engine configuration of 275 to 350 horsepower. Each engine is different based on the customized usage of the customer and the history of the machine.

You should remember the amount of time you have used it and the total output you have derived from it.

If there is an issue with the horsepower then it is best to use this history before you try to fix your engine.

Remote Issues

Things that come with wireless remotes can have two main issues and this goes generally for all remote-operated devices:

- You may notice a loss of radio signal because of the sensor in the remote or a sensor in your chipper. 2.

It could be that your remote is out of batteries or the battery slot is damaged. Either way the remote will not be able to contact the chipper and hence not be able to send the right signals.

If the remote is problematic a standard remote replacement will fix it. If the receiver in the chipper is problematic then you need to replace it. But, first, find out where the issue lies.

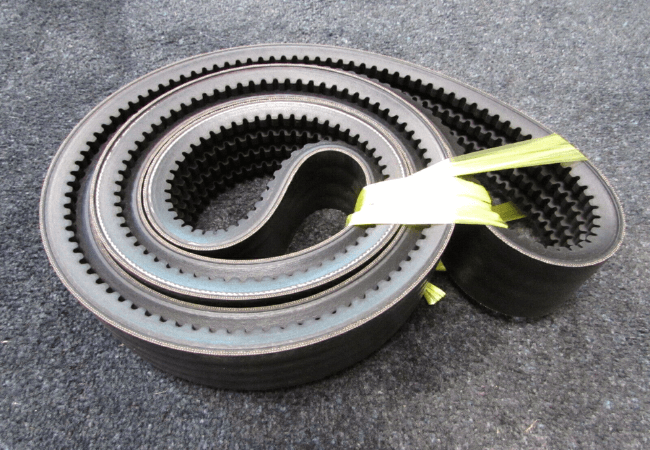

Check the drive belt

It could be that your drive belt on the shredder of your chipper is overused, or somehow damaged.

A quick way to check this if the engine is running and it looks fine to you but the chipper is not turned on or getting the supply it needs to run.

This happens when the belt is worn off, the belt will either slip or cause a wobbly movement whereby the blades will not turn effectively causing no chipping action to actually turn up because there is not feed or grinding.

The Blades

The blades need to be sharpened from time to time. You should remember the recommended factory angle for sharpening them if you do not want to wear them out prematurely or without giving you full use value.

You can sharpen them between a range of 20-45 degrees but it will vary from model to model as well. Be careful to read out the safety manual before you attempt to sharpen the blades of the chipper.

The blades will give you issues if you do not sharpen them timely, and here timely means after every six hours of using them. This also means after six hours of using either straight or in short batches.

If you do not do this enough they will become very dull and stop working. It will reduce the life of the chipper as well and in some cases, it can heat up the machine too much.

If you are however processing only very old dried branches or autumn trees then the blades will require you to sharpen much more frequently than six hours of work. If your blades are dull then the self-feeding action of the chipper will be affected as well.

It may stop working completely or the performance may decline and cause problems.

Anvil Issues

If you are suspecting that the anvil is damaged as if it got hit by something then you should know that an anvil can take up to 3 hits before it stops working or loses performance completely.

This means that you can get about 25 good uses out of it before you have to replace it. if you use your chipper with greater caution then you can increase the lifespan of your Anvil.

Some Recommendations and Hints

Use these recommendations as hints to understand what went wrong and how to prevent it the next time. You should first and foremost keep your machine clean. No gunk should be in the machine, it should not be left outside the shed in the pouring rain mildew, or snow. You should always keep it covered under a waterproof cover or a sheet when not in use.

Second of all keep your blades sharp in order to prevent them from losing touch in time. This means touching them up every now and then. Do not overheat them when they are not working their best results for you, sharpen them as you go and you will be able to prevent many issues.

Keep your brakes adjusted which means that the brakes have to be in optimal condition so you can prevent any unwanted hits or damage to the engine. You should also be mindful of selecting the right replacement parts and installing them properly if not professionally which is the ideal way to go.

Lastly, maintain your chipper well. Grease the bearings from time to time and clean out the air filter timely. Following basic maintenance recommendations will prevent forseeable damage and make sure that your machine is working as neatly as possible.

This also means that you will be able to get maximum use out of your machine with the least amount of servicing or troubleshooting needed saving your time to be more productive.

BANDIT Hand-Fed Chippers: Safety, Start-Up, Operation, & Maintenance

Using Warranties For Chippers

Bandit as a company provides it’s machines with a 1-year to 2,000-hour manufacturer’s warranty that can be claimed at its factories or service centers. This gives a lot of peace of mind especially because there are rarely any issues with the machines.

If you do not notice an issue arising with your machine or a machine within this time frame just simply contact their support team and they will handle it for you. If you are out of the time then it is a good idea to purchase an extended warranty or get it repaired by paying the part cost of what piece is damaged.

The extended warranty is for 5 years or 3000 hours, as compared to the one that comes with the machine. You can try and replace the parts with cheaper or second hand parts once you know the cause but it will render your warranty void.

You should also not try to fix any part on your own as it took engineers to build it and you do not want to mess with a nuanced piece of machinery. Goodluck! We hope this helps!